Design

The Project Scope includes:

-

Technical support for project participants, including measurements at the target site, reviews, assumptions, guidelines, and inter-branch agreements.

-

Project Documentation developed to achieve solutions that meet the required technical parameters and operating conditions, while also being the most cost-effective for the investment budget, including:

- Calculations of basic busbar dimensions for specified temperature limits,

- Determination of electrical loss levels,

- Calculation of forces and stresses occurring in busbars during short circuits,

- Verification of the correctness of material and geometry selection for busbars,

- Determination of forces transferred to support structures,

- Calculations of cross-sections of busbars and conductors at grounding points,

- Drawings of busbar routes and connections to equipment,

- 3D model of busbar routes and connections to equipment,

- Drawings of busbar penetrations through building walls,

- Busbar grounding diagrams,

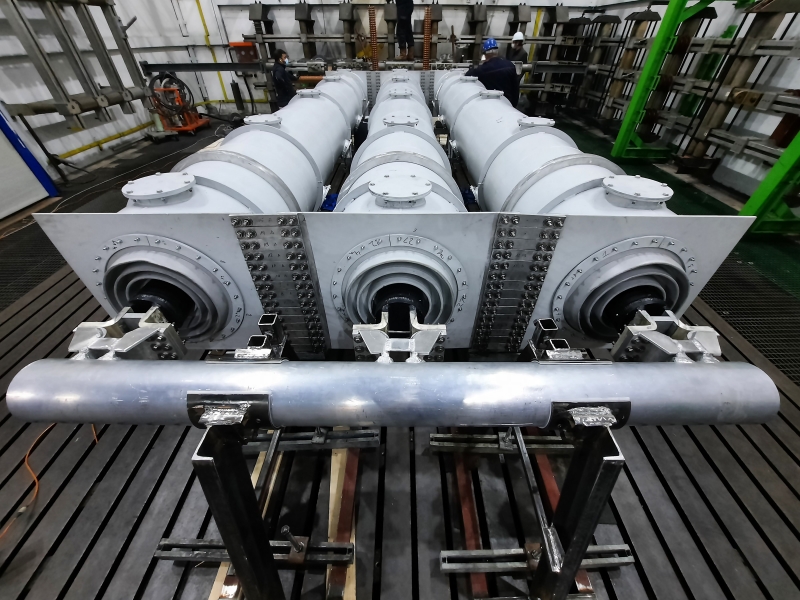

- Diagrams and structural details of pressurization systems in the busbar.

-

Acceptance Documentation, which includes, among others:

- Drawings, technical descriptions, technical data sheets,

- Voltage test reports, insulation resistance measurement reports, bolted joint reports,

- Paint coating measurement reports,

- Welding Procedure Specifications (WPS), welder certificates,

- Certificates, attestations, and approvals for applied materials and components,

- Operation and Maintenance Documentation,

- Declaration of Conformity,

- Statement of commissioning for operation,

- Warranty.